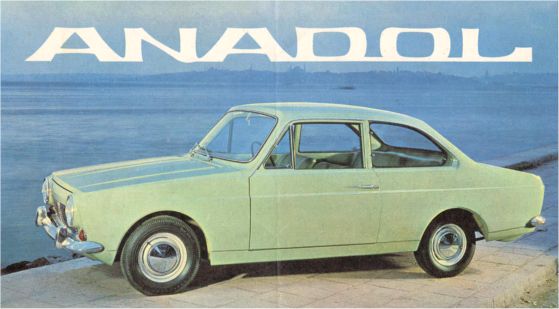

The early 1970s marked a pivotal moment in automotive history when emerging markets began developing their domestic car industries. Turkey’s entrance into this arena came through an ambitious project that would forever change the country’s industrial landscape. The Anadol A1 1.3 emerged as more than just a car—it represented a nation’s leap into modern manufacturing.

This two-door sedan carried the hopes of an entire industry on its fiberglass shoulders. When the 1972 model rolled off the production line, it showcased Turkey’s capability to compete in the global automotive market. The A1 1.3 wasn’t just another car—it was a statement of technological independence.

Breaking Ground with Revolutionary Construction

The Anadol A1 1.3’s most striking feature wasn’t immediately visible to the casual observer. While other manufacturers relied on traditional steel construction, Anadol boldly opted for a fiberglass body. This decision sparked both innovation and skepticism in the automotive community.

Fact!

The A1's fiberglass body construction reduced its weight to just 830 kg, making it one of the lightest sedans in its class during the early 1970s.

The collaboration between Turkish engineers and British design house Ogle Design yielded unexpected benefits. The lightweight construction allowed for improved fuel efficiency and easier manufacturing processes, though it presented unique challenges for repairs and maintenance.

“The A1’s construction was ahead of its time. Working on these cars today, you can appreciate the innovative thinking that went into their design. The fiberglass body has actually helped many examples survive longer than their steel counterparts from the same era.” — James Mitchell, Classic Car Restorer at European Vintage Automotive

The manufacturing process required entirely new skill sets and training programs, effectively creating a new class of automotive craftsmen in Turkey. This expertise would later prove valuable for the country’s expanding industrial base.

Engineering Excellence Under the Hood

The heart of the A1 1.3 beat with British engineering precision. The Ford Kent engine, producing 54 horsepower from its 1298cc displacement, proved to be a reliable powerplant that balanced performance with practicality.

Performance figures tell an interesting story:

- 0-100 km/h acceleration in 20 seconds;

- top speed of 135 km/h;

- four-speed manual transmission;

- rear-wheel drive configuration.

These specifications might seem modest by today’s standards, but they were competitive for the era and market segment. The A1 1.3’s lightweight construction helped maximize the engine’s potential.

Racing Heritage and Performance Evolution

Few cars can claim to have created their own racing category, but the Anadol A1 1.3 did exactly that. The car’s lightweight construction and robust Ford engine made it an ideal platform for motorsport modification.

“In the early ’70s, seeing an Anadol on the racetrack was a source of national pride. These cars proved that Turkish engineering could compete internationally.” — Ahmet Yilmaz, Vintage Racing Historian

Local racing success helped establish the model’s performance credentials. Weekend racers discovered that the fiberglass body allowed for easier modifications and repairs compared to conventional steel cars.

The racing program also drove continuous improvements in the road car’s design. Each competition victory added to the brand’s prestige and convinced skeptics of the car’s durability.

Cultural Impact and Historical Significance

The Anadol A1 1.3 transcended its role as mere transportation. It became a symbol of Turkish industrial capability and modernization. The 1972 model year represented the peak of the design’s evolution, incorporating lessons learned from earlier production runs.

Historical Reference!

The A1's production run from 1966 to 1975 coincided with Turkey's rapid industrialization period, making it a symbol of national progress and economic development.

Production numbers tell only part of the story. The real impact lies in the thousands of engineers, technicians, and workers who gained valuable experience through the program. This knowledge base would prove crucial for Turkey’s future automotive ventures.

Future Classic Status and Collector Appeal

As we look back from 2025, the Anadol A1 1.3 stands as more than just Turkey’s first mass-produced car. It represents a crucial chapter in automotive history where innovative materials and manufacturing techniques merged with traditional engineering principles.

The surviving examples serve as rolling museums, each telling the story of a nation’s industrial coming of age. Their increasing value among collectors reflects growing appreciation for their historical significance and unique engineering solutions.

| Pros | Cons |

|---|---|

| Revolutionary fiberglass construction reduced weight | Limited repair options for body damage |

| Reliable Ford Kent engine with proven track record | Modest performance by modern standards |

| Historical significance as Turkey’s first mass-produced car | Parts availability can be challenging |

| Innovative design collaboration with British expertise | Limited production numbers affect restoration options |

| Strong racing heritage and competition success | Requires specialized knowledge for maintenance |

| Excellent survival rate due to non-corrosive body | Original trim pieces are increasingly rare |

The Anadol A1 1.3 demonstrates how innovation often emerges from necessity. While it may not have achieved global sales success, its influence on Turkish industry and automotive engineering extends far beyond its production numbers. Today, it stands as a testament to the power of ambitious engineering and national determination.